Understanding C5 Petroleum Resin: Types, Properties, and Industrial Applications

2025-04-29

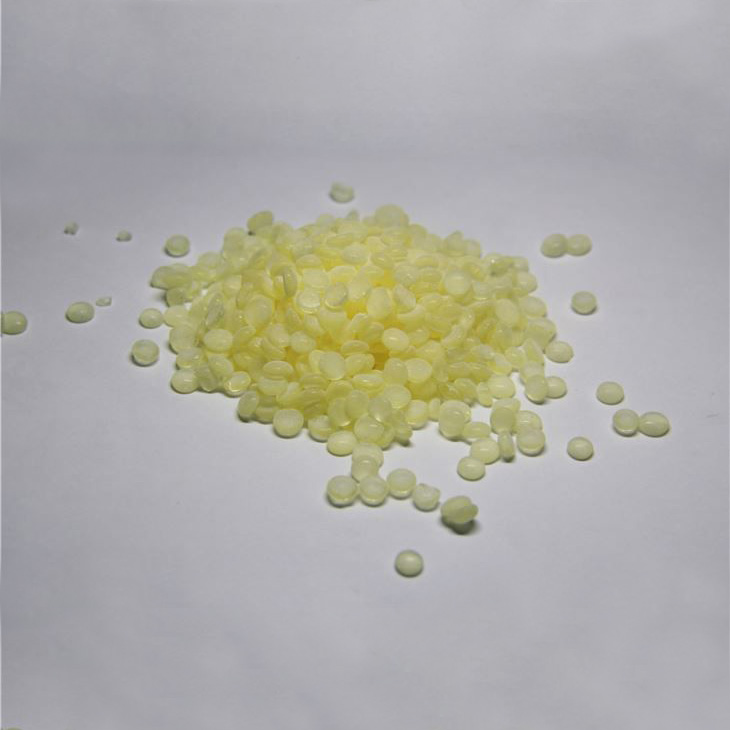

In the world of adhesive formulations, rubber compounding, and coatings, C5 petroleum resin plays a crucial role as a performance-enhancing additive. Known for its tackifying properties and compatibility with various base materials, C5 resin enhances product adhesion, flexibility, and thermal stability. But not all C5 resins are created equal. Based on raw materials and synthesis methods, C5 petroleum resins can be divided into five distinct types—each offering specific advantages for industrial applications.

Let’s explore these classifications and their respective features:

1. Mixed Resin

Mixed resin is the most commonly produced type of C5 petroleum resin. It is synthesized from either separated or unseparated C5 fractions through a high-temperature polymerization process. This method is straightforward and efficient, yielding a versatile resin that can be used across multiple industries including adhesives, coatings, and rubber modification.

Key Characteristics:

· Standard performance at a reasonable cost

· Balanced compatibility with rubber and non-polar substrates

· Suitable for general-purpose industrial applications

2. Aliphatic C5 Resin

Composed mainly of concentrated piperylene, the aliphatic C5 resin stands out for its improved resistance to heat and weather. It features a lower softening point and is compatible with non-polar polymers, making it ideal for rubber-based adhesives and sealants.

Key Benefits:

· Excellent thermal and UV resistance

· Good solubility in aliphatic solvents

· Ideal for applications requiring long-term durability

3. DCPD Aliphatic Petroleum Resin

Derived from high-purity DCPD (dicyclopentadiene), this resin is unsaturated and inherently unstable, meaning it cannot be used directly in its raw form. However, it serves as a precursor for advanced, modified resins, including hydrogenated variants used in high-end adhesive products.

Application Insight:

· Used as a base material for modified resins

· Integral in the production of upgraded, specialty resin types

· Requires stabilization or further processing before application

Choosing the right type of C5 petroleum resin depends on your specific application, budget, and performance requirements. From cost-efficient mixed resins to high-performance hydrogenated grades, each category brings unique value to modern manufacturing.

Whether you're formulating industrial adhesives or customizing performance rubbers, understanding these five types helps you make more informed, strategic decisions. As industries increasingly demand versatility, clarity, and durability, C5 petroleum resins continue to evolve, offering reliable solutions across sectors.