The Role of the Press Die Mold Components in Holding the Upper Die in Place

2024-05-31

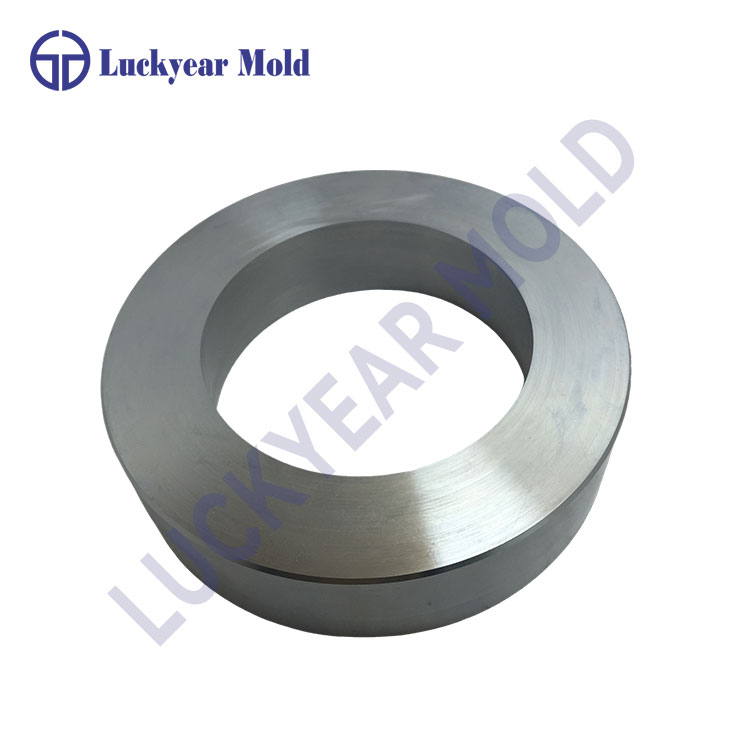

In the intricate world of metal forming and stamping, press die molds are precision tools that require a meticulous balance of strength, accuracy, and durability. One of the most crucial aspects of these molds is how they securely hold the upper die, also known as the punch, in place.

The upper die, which descends into the fixed lower die to shape the metal workpiece, must be firmly secured to ensure precise and repeatable results. The question is: what part of the press die mold is responsible for this vital task?

The answer lies in the press die mold's guiding system. This system typically consists of precision-engineered guides and guide pins that are integrated into the mold's design. These components work together to provide stability and alignment for the upper die, ensuring that it moves smoothly and accurately during the stamping process.

The guiding system is designed to withstand the significant forces and pressures exerted during metal forming. It must be able to keep the upper die aligned and positioned correctly, even under extreme conditions. This ensures that the metal workpiece is properly shaped and formed, minimizing waste and maximizing productivity.

In addition to the guiding system, other components of the press die mold also play a role in holding the upper die in place. These include the die holder, which provides a secure mounting point for the upper die, and the press ram, which applies the necessary force to drive the upper die into the lower die.

The design and construction of the guiding system are crucial to the performance and longevity of the press die mold. A poorly designed or worn-out guiding system can lead to misalignment, damage to the mold components, and inconsistent results. Therefore, it is essential to maintain and inspect the guiding system regularly to ensure that it is functioning properly.

In conclusion, the guiding system of the press die mold is responsible for holding the upper die in place and ensuring its smooth and accurate movement during the stamping process. By understanding the role of this system and maintaining it properly, manufacturers can optimize the performance and productivity of their press die molds.