Exploring the Advantages of Double-Sided PET White Film Flexible Circuit Boards

2024-09-04

As the demand for smaller, lighter, and more versatile electronic devices grows, the need for innovative materials and components has become increasingly important. One such innovation is the Double-Sided PET White Film Flexible Circuit Board (FCB). In this blog, we'll dive into what makes these circuit boards unique and how they are revolutionizing the electronics industry.

What is a Double-Sided PET White Film Flexible Circuit Board?

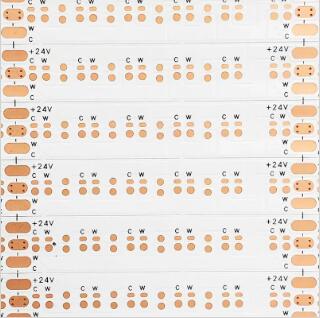

A Double-Sided PET White Film Flexible Circuit Board is a type of flexible circuit board that uses PET (Polyethylene Terephthalate) as its base material. PET is a highly durable, lightweight, and flexible polymer that provides excellent electrical insulation. The "double-sided" aspect means that conductive traces are printed on both sides of the PET film, allowing for more complex and compact circuit designs.

Key Advantages of Double-Sided PET White Film FCBs

1. Flexibility and Durability

One of the most significant advantages of using PET as the base material is its flexibility. These circuit boards can bend, fold, and twist without compromising their electrical integrity. This flexibility is particularly beneficial in applications where space is limited, and the circuit needs to conform to non-flat surfaces.

2. Lightweight Design

PET is much lighter than traditional rigid circuit board materials like FR4. This weight reduction is critical in industries like aerospace, automotive, and wearable electronics, where every gram counts.

3. Excellent Insulation Properties

PET offers superior electrical insulation, ensuring that the conductive traces remain isolated from each other even in tightly packed designs. This high insulation reduces the risk of short circuits and enhances the overall reliability of the device.

4. Cost-Effectiveness

Compared to other flexible circuit board materials like polyimide, PET is more cost-effective. It provides a good balance between performance and price, making it an attractive option for mass-produced consumer electronics.

5. Enhanced Design Flexibility

With conductive traces on both sides of the PET film, designers can create more complex circuits without increasing the board's size. This capability allows for more compact and efficient electronic devices.

Applications of Double-Sided PET White Film FCBs

1. Wearable Electronics

The lightweight and flexible nature of PET-based FCBs makes them ideal for wearable devices like fitness trackers, smartwatches, and medical sensors. These boards can comfortably fit into the curved and flexible surfaces of wearable gadgets.

2. Automotive Industry

In the automotive sector, these flexible circuit boards are used in applications where traditional rigid boards would be impractical, such as in dashboards, lighting systems, and sensor arrays.

3. Consumer Electronics

From smartphones to tablets, Double-Sided PET White Film FCBs are used in various consumer electronics to save space and reduce weight while maintaining high performance.

4. Medical Devices

In the medical field, these circuit boards are used in devices that require both flexibility and durability, such as portable diagnostic tools, sensors, and implants.

Conclusion

The Double-Sided PET White Film Flexible Circuit Board represents a significant advancement in electronic design and manufacturing. Its unique combination of flexibility, durability, and cost-effectiveness makes it an essential component in the next generation of electronic devices. As technology continues to evolve, these flexible circuit boards will play an increasingly important role in various industries, pushing the boundaries of what is possible.