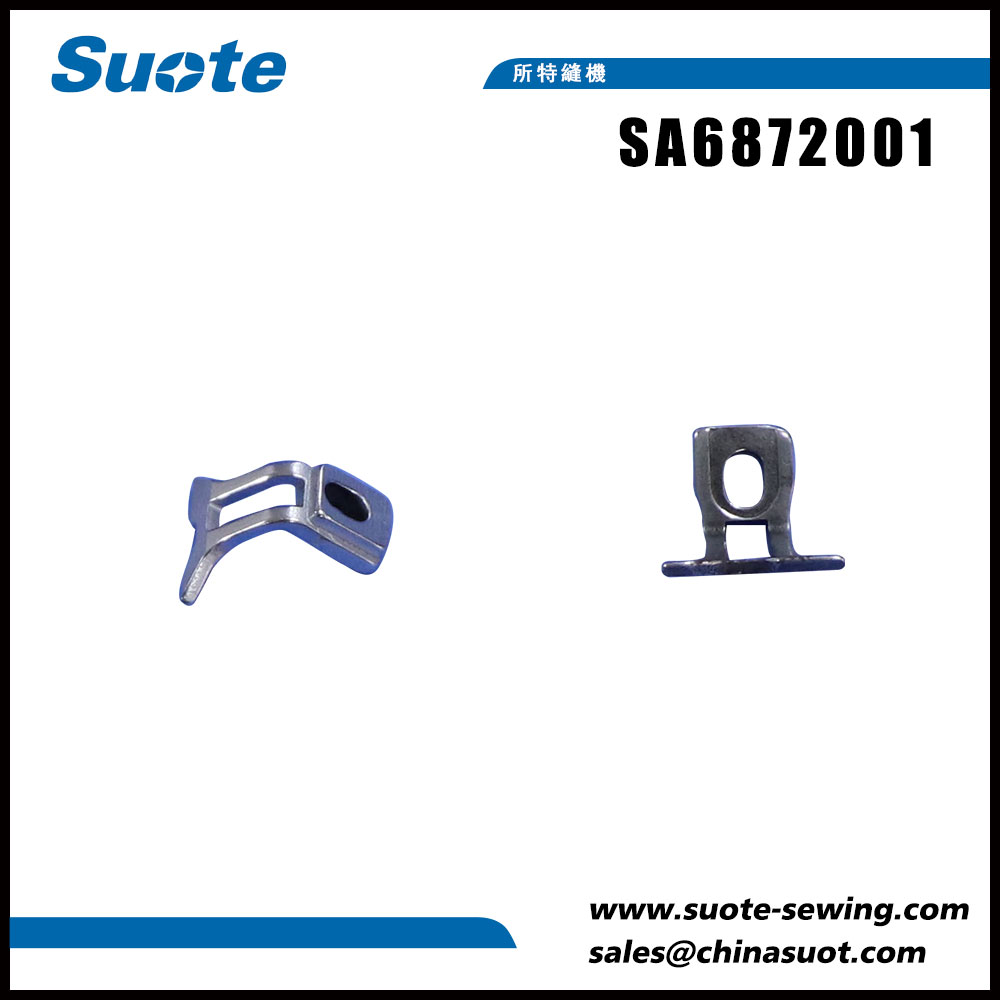

Exploring Considerations: Limitations and Drawbacks of SA6872001 Needle Guard U

2024-04-02

Introduction:

As with any innovative product, it's essential to consider potential limitations or drawbacks to using the SA6872001 Needle Guard U. While this needle safety device offers significant advantages in mitigating the risk of needlestick injuries, it's crucial to understand any limitations to its effectiveness. In this blog, we'll delve into the possible drawbacks of the SA6872001 Needle Guard U, providing insights to help users make informed decisions about its implementation.

Limited Compatibility with Specialty Needles:

While the SA6872001 Needle Guard U boasts versatility in accommodating various needle sizes commonly used in healthcare and laboratory settings, it may have limitations with certain specialty needles. Some specialized needles, such as those used in specific medical procedures or research applications, may not be compatible with the standard design of the SA6872001 Needle Guard U. In such cases, users may need to explore alternative safety measures or consult with the manufacturer to assess compatibility.

Initial Investment and Cost Considerations:

Another potential drawback of the SA6872001 Needle Guard U is the initial investment required for purchasing and implementing the device. While the long-term benefits of reducing needlestick injuries and enhancing workplace safety are undeniable, organizations must consider the upfront costs associated with acquiring and integrating this safety device into their existing processes. Additionally, ongoing maintenance and replacement costs should be factored into the overall cost analysis to ensure cost-effectiveness over time.

Training and Education Requirements:

Effective utilization of the SA6872001 Needle Guard U relies on proper training and education for healthcare professionals, laboratory technicians, and other users. While the device is designed to be user-friendly, organizations may need to allocate resources for training sessions to ensure that staff members understand the device's features, activation mechanism, and best practices for safe use. Failure to provide adequate training could diminish the device's effectiveness and compromise its ability to prevent needlestick injuries.

Potential Workflow Disruptions:

Introducing a new safety device like the SA6872001 Needle Guard U into existing workflows may lead to temporary disruptions as users adapt to the change. Healthcare facilities, laboratories, and manufacturing plants must anticipate potential workflow adjustments and allocate sufficient time for staff members to familiarize themselves with the device. Additionally, organizations should establish clear communication channels to address any concerns or challenges that arise during the implementation process, minimizing disruptions and ensuring a smooth transition.

Conclusion:

While the SA6872001 Needle Guard U offers significant benefits in enhancing needle safety and reducing the risk of needlestick injuries, it's essential to acknowledge potential limitations and drawbacks associated with its use. By carefully considering factors such as compatibility with specialty needles, initial investment costs, training requirements, and potential workflow disruptions, organizations can make informed decisions about the implementation of the SA6872001 Needle Guard U. Ultimately, addressing these considerations proactively can help maximize the effectiveness of this innovative safety device and ensure a safer working environment for all.