Ensuring Longevity: Maintenance Requirements for Large Diameter Stringing Blocks

2024-05-15

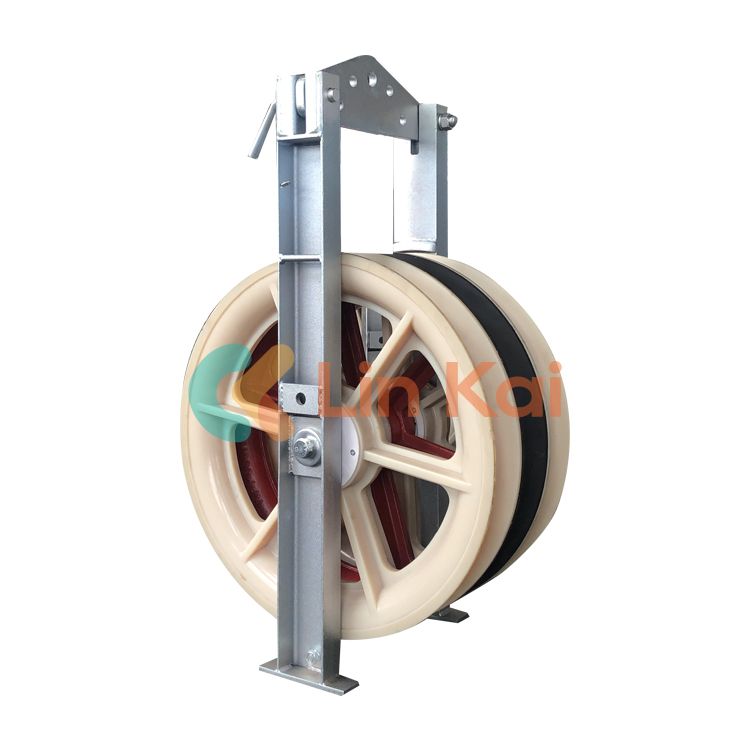

Large Diameter Stringing Blocks are vital tools in the power line industry, facilitating the smooth and efficient installation of overhead power lines. To maintain their functionality, reliability, and safety, proper maintenance of these blocks is essential. Regular inspections, cleaning, and servicing help prevent wear and ensure optimal performance. Let's delve into the maintenance requirements for Large Diameter Stringing Blocks and why they are crucial for the success of power line projects.

Importance of Maintenance

Large Diameter Stringing Blocks are subjected to demanding conditions during stringing operations, including heavy loads, friction, and exposure to the elements. Without regular maintenance, these factors can lead to wear, corrosion, and potential failure, jeopardizing the safety and efficiency of stringing operations.

Key Maintenance Requirements

1. Regular Inspections

Regular inspections are essential for identifying any signs of wear, damage, or malfunction.

- Visual Checks: Inspect the entire block for cracks, dents, or signs of corrosion. Pay attention to critical components such as the sheaves, bearings, frames, and mounting hardware.

- Functional Checks: Ensure that all moving parts operate smoothly and that safety features such as latches and locks function correctly.

2. Cleaning and Lubrication

Keeping the stringing blocks clean and properly lubricated is crucial for maintaining smooth operation and preventing corrosion.

- Cleaning: Remove dirt, debris, and any contaminants from the block using a mild detergent and water. Pay particular attention to the sheaves and bearings.

- Lubrication: Apply a suitable lubricant to the bearings and other moving parts according to the manufacturer's recommendations. This helps reduce friction and wear and ensures smooth rotation.

3. Replacement of Worn or Damaged Parts

Components that show signs of wear or damage should be replaced promptly to prevent further deterioration.

- Sheaves: If the sheaves show signs of wear, such as grooves or rough surfaces, they should be replaced to maintain proper conductor alignment and reduce friction.

- Bearings: Worn or damaged bearings should be replaced to ensure smooth rotation and prevent mechanical issues.

4. Alignment and Tension Adjustment

Proper alignment and tension are crucial for the effective operation of Large Diameter Stringing Blocks.

- Alignment: Ensure that the sheaves are aligned properly to prevent the conductor from slipping or becoming misaligned during stringing operations.

- Tension Adjustment: Check the tension settings and adjust them as needed to accommodate different conductor sizes and loads.

5. Corrosion Protection

Stringing blocks are often exposed to harsh environmental conditions, making corrosion protection essential.

- Corrosion Inhibitors: Apply corrosion inhibitors or coatings to vulnerable areas to protect against rust and corrosion.

- Galvanization: For metal components, galvanization provides an additional layer of protection against corrosion.

6. Documentation and Record-Keeping

Maintaining detailed records of maintenance activities is essential for tracking the condition of stringing blocks and identifying any recurring issues.

- Maintenance Logs: Keep records of inspections, repairs, and replacements performed on each stringing block.

- Service Schedule: Establish a regular maintenance schedule based on manufacturer recommendations and operational experience.

Conclusion

Maintaining Large Diameter Stringing Blocks is essential for ensuring their longevity, reliability, and safety. Regular inspections, cleaning, lubrication, replacement of worn parts, and corrosion protection measures are all critical aspects of proper maintenance. By adhering to a comprehensive maintenance program, power line professionals can maximize the performance of stringing blocks, leading to efficient and successful power line installations. As the backbone of power infrastructure, these maintenance efforts play a crucial role in ensuring the continued delivery of reliable electricity to communities around the world.