Enhancing Condensation Resistance: The Impact of the 12A Middle Glass Warm Edge Spacer on Insulated Glass Units

2024-05-24

In the realm of modern building design, energy efficiency and indoor air quality are paramount. A key aspect of achieving these goals lies in addressing the issue of condensation in insulated glass units (IGUs). The 12A Middle Glass Warm Edge Spacer represents a significant advancement in this area, offering superior condensation resistance. In this blog, we will explore how this innovative spacer enhances condensation resistance and contributes to the overall performance of IGUs.

Understanding Condensation in IGUs

Condensation occurs when moist air comes into contact with a cooler surface, leading to the formation of water droplets. In windows, this typically happens along the edges of the glass, where traditional aluminum spacers can cause the surface to cool more rapidly due to their high thermal conductivity. This not only compromises the clarity and aesthetics of the glass but can also lead to mold growth, frame damage, and reduced thermal efficiency.

How the 12A Middle Glass Warm Edge Spacer Improves Condensation Resistance

1. Low Thermal Conductivity Materials

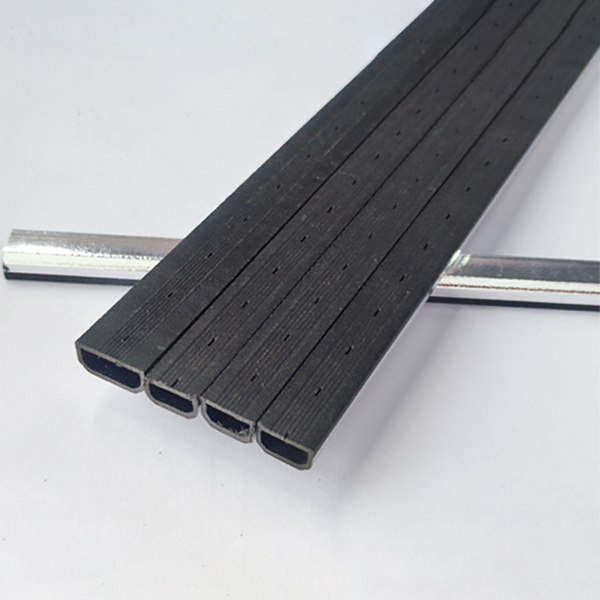

The 12A Middle Glass Warm Edge Spacer is made from materials with low thermal conductivity, such as polymeric composites. Unlike aluminum, these materials do not conduct heat and cold as efficiently, which helps to keep the edges of the glass warmer.

- Minimizing Thermal Bridging: The low conductivity of the spacer reduces thermal bridging, a major contributor to condensation. By keeping the temperature at the edges of the glass closer to the room temperature, the risk of condensation forming is significantly reduced.

2. Enhanced Edge Temperature

Maintaining a higher edge temperature is crucial in preventing condensation. The 12A spacer ensures that the edges of the IGU do not become cold spots.

- Warm Edge Technology: By incorporating warm edge technology, the 12A spacer helps to maintain a more consistent temperature across the entire surface of the glass, reducing the likelihood of condensation forming at the edges.

3. Effective Moisture Absorption

The 12A Middle Glass Warm Edge Spacer integrates advanced desiccants within its structure. These desiccants are designed to absorb any moisture that may infiltrate the IGU, further enhancing condensation resistance.

- Desiccant Performance: The high-quality desiccants used in the 12A spacer absorb moisture effectively, ensuring that the interior of the IGU remains dry and free from condensation, even in varying humidity conditions.

4. Superior Sealing Technology

The spacer utilizes advanced sealants that maintain their integrity over time, ensuring a robust and airtight seal.

- Durable Sealants: The use of butyl-based sealants provides an excellent barrier against moisture ingress, preventing condensation from forming inside the IGU. These sealants are flexible and durable, accommodating the natural expansion and contraction of the window components.

Benefits of Enhanced Condensation Resistance

1. Improved Visual Clarity

Condensation on windows can obscure views and detract from the aesthetic appeal of a building. By preventing condensation, the 12A spacer helps maintain clear and unobstructed views.

2. Enhanced Indoor Air Quality

Condensation can lead to mold growth, which poses health risks to building occupants. The 12A spacer’s ability to prevent condensation helps maintain a healthier indoor environment by reducing the potential for mold and mildew.

3. Increased Thermal Efficiency

By minimizing thermal bridging and preventing moisture-related issues, the 12A spacer contributes to the overall thermal efficiency of the IGU. This leads to more consistent indoor temperatures and reduced energy consumption for heating and cooling.

4. Extended Lifespan of IGUs

Condensation can damage window frames and seals, leading to premature failure of the IGU. The 12A spacer’s superior condensation resistance helps extend the lifespan of windows, reducing the need for repairs and replacements.

Conclusion

The 12A Middle Glass Warm Edge Spacer plays a crucial role in enhancing the condensation resistance of insulated glass units. By utilizing low thermal conductivity materials, maintaining higher edge temperatures, incorporating effective desiccants, and employing advanced sealing technology, this spacer significantly reduces the risk of condensation. The result is improved visual clarity, better indoor air quality, increased thermal efficiency, and longer-lasting IGUs.

For both residential and commercial applications, the 12A Middle Glass Warm Edge Spacer represents a smart investment in building performance and occupant comfort. As we continue to prioritize energy efficiency and sustainability in building design, innovations like the 12A spacer will be instrumental in achieving these goals.